For the non-woven manufacturing process, we offer plastic and metallic belts and conveyors for each step from web forming to bonding.

Our fabrics are made from various materials:

Polyester, polyamide, conductive yarns, kynar (PVDF), PPS, stainless steel and bronze.

- Weaving: up to 18’ -6 m- wide

- Aperture: from 150 to 1600 CFM

- Seams: endless woven or non marking pin seam

Web bonding

-

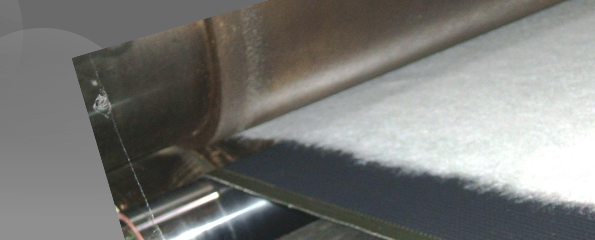

- Thermal bonding:

Metal wire cloth, made endless by means of a soldered gold seam. These fabrics can withstand temperatures up to 350° Celsius – 662 degree Fahrenheit – and are very durable.

-

- Spunlace/ Hydroentanglement:

For this process we offer our customers different fine to very fine, single layer polyester cloths, endless woven. We also offer very open mesh to dry the product, often using guiding profiles on the edge the belt.

Web formation

We offer different wire cloths with an adapted air permeability level, a suitable support of fibres and eventually conductive properties.

Particularly responding to the needs of web formation, the design of our wires provides web stability, good lay down of fibres and optimal removal of the nonwoven.

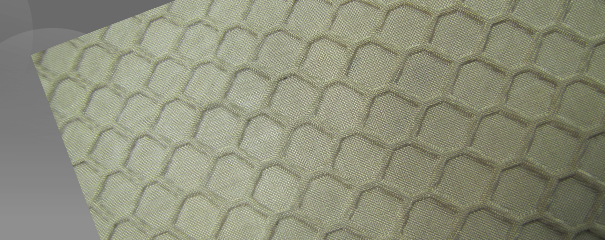

Patterning & Drying cylenders

Depending on the manufacturing process : carding, airlaid, wetlaid as well as spunbond/meltblown, we offer different wire cloths with an adapted air permeability level, a suitable support of fibres and eventually conductive properties.

Particularly responding to the needs of web formation, the design of our wires provides web stability, good lay down of fibres and optimal removal of the nonwoven.

Our References